TREND AND APPLICATIONS OF ABSORPTION CHILLER

Sea Group

B.C. Chung - Century Corporation, Korea

1. INTRODUCTION

Since human being's desire for comfortable environment is

instinctive, demand for HVAC increasingly grows as one's increases. Therefore

propagation of air-conditioning facility is highly enlarged in countries which

have been achieving economic growth. At present, most of the popular chillers

as large tonnage of air conditioners are electrically driven. These electric

chillers, which work perfectly under sufficient power supply, are causing

a great deal of problems when the electric power condition is poor. In this

area, the electric chiller is not proper to carry out varying cooling load

according to the seasonal changes a peak load in some seasons and a partial

load in other seasons. The electrically driven chiller have some problems

something like this. In this case, the electric power condition can be improved

by replacing the electric chiller system with those which use different types

of energy, which is relatively sufficient compared with electricity. In general,

when there is a peak load for air conditioning in a building, about 20% of

the total electric power consumption is due to the air-conditioning system. Furthermore, electric chillers consume 70%

out of the 20%, which amounts to 14% of total electric power consumption.

Therefore it is required to substitution these electric chillers to non-electric

ones to cope with an electric power shortage. A representative of non-electric

chiller is an absorption type. The absorption chiller consumes only 5∼10%

electric power compare with an electric chiller, as auxiliary power and power

for control. The main energy can be used several kind of heat source, for

instance gas fuel, liquid fuel, steam, hot water, solar heat, high temperature

exhaust gas, etc. instead of electricity. About 12∼13% of the total electric

power consumption in a building can be saved if an absorption type is adopted.

Therefore if the absorption chillers are adopted on a nationwide scale, it

is an effective and efficient solution to solve problems associated with an

electric power shortage. Since any heat energy that has high temperature but

has been wasted, and than if it can be used as a driving heat source of the

absorption chiller, it is more useful energy saving application of the absorption

chiller. The absorption chiller utilizes distilled water as a refrigerant

not freon. Hence it is very friendly to the global environment.

2. ADVANTAGE OF ABSORPTION CHILLER

1) Electric power consumption is only 1/20∼1/10 of

a vapor compression type chiller.

The comparison for the electric power consumption is as follows

in case a 170 usRT chilled installed. The electric power consumption is around

187 kWh when an electrically driven centrifugal chiller and a boiler are installed

as a HVAC system. Here the centrifugal chiller consumes about 130 kWh and

takes up nearly 70% of the electric power consumption of the entire air-conditioning

system. On the contrary, if a direct-fired double effect absorption chiller

installed, the power consumption of the entire air-conditioning system can

be reduce to 70 kWh. In this case the direct-fired double effect absorption

chiller consumes about 8 kWh, which is only 6.1% of the electric power consumption

of the centrifugal chiller.

2) Contributes to prevention of environmental pollution by

introducing non-freon refrigerant.

Centrifugal chillers mainly used for the cooling load of

more than 100 usRT and they have used R123 as a refrigerant whose ODP(Ozen

Deplection Potential) is 0.022 and GWP(Global Warming Potential) is 0.02.

From several years ago, it is in the process of replacing R123 with R134a

whose ODP is 0 and GWP is 0.29. But, because the GWP of R134a is very higher

than R123's, R134a is not a complete alternative refrigerant. On the contrary,

the absorption chiller utilizes distilled water as a refrigerant, and lithium

bromide solution as a absorbent. The absorbent is also stable and unharmful

to the human body. Hence the absorption type is very favorable to the environment.

3) The system is safe since it is operated under vacuum state.

Water serving as a refrigerant evaporates at 5℃, condenses

at 40℃,

and regenerates at 90℃

during operation of the fully vacuumed absorption chiller. This is meaning

that the system maintains vacuum condition in operation. So, there is no chance

for the system to experience physical damage of explosion.

4) Saving installation area

In case of heating and cooling are required, the direct fired

absorption chiller heater system reduces required installation area by 40%

when compared with a system composed of an electric centrifugal chiller and

a boiler. Consequently, the absorption chiller heater system increases availability

of the building.

5) Operating characteristics under a partial load are excellent.

The chillers are operated under a partial load rating between

50 and 70% for the most period of operation. And then, the absorption chiller

has higher efficiency at partial load operation more than full load operation.

It is also higher compare with the electrically driven centrifugal chiller.

Thus absorption chiller system can save running cost to a great extent.

3. TREND OF ABSORPTION TYPE IN KOREA

The typical outdoor temperature in Korea is in the range

of 28 ∼

38℃

in summer and 5 ∼

-20℃

in winter. Therefore energy consumption patterns are very much different from

season to season like as shown in Fig. 1. The electric power consumption and the fuel oil consumption

cross each other to the opposite direction in a period of 1 year. This requires

facility which corresponds to the maximum consumption of both energy types.

However the operating time under a peak load is relatively short. Accordingly

the Korean government makes every effort to reduce these maximum points.

|

|

Fig. 1.

DEMAND PATTERNS OF LNG AND ELECTRICITY

1) The policy and circumstances of electric power in Korea.

The maximum electric power demand reached 41,007 MW in August,

2000. And then, the electric power consumption for air conditioning systems

takes around 20% of the total power consumption under the peak load in Korea.

And the amount of the power used for the air-conditioning is 8,073 MW which

amounts to the power generated by the 8th nuclear power plants.(Total construction

expense is approximately $9.2 billion.) The Korean government is in the process

of considering and carrying various policies. Typical examples are as follows.

(1) Enhancing propagation of the absorption chiller and ice

storge system.

(2) Enhancing propagation of high efficiency appliances.

(3) Enlarging the role of co-generation facility and emergency

electric generators.

(4) Power late policy for demand management.

Among the above countermeasures, propagation of the absorption

chiller is enlarged through the policies

as belows.

2) Policy and subsidy for augmenting propagation of absorption

of chiller.

(1) Financing for the purchase of the facility.

(2) Applying discounted gas rates.

(3) Reduction and exemption from taxes.

(4) Discounting the installation cost for city gas piping.

(5) Mandatory installation of the gas-fired absorption chiller

for new buildings.

(6) Restrictive policy for the types of fuel.

(7) Korea Electric Power Institute has started providing

a loan, and renting the absorption chiller system.

4. NEW APPLICATIONS OF ABSORPTION CYCLE IN KOREA

As advanced comments, the korean government adopted various

policies to reduce the electric peak

load in summer season. One is the installation of the district co-generation

system which produces electric power by generator and produces hot water by

wasted heat. The hot water is used for absorption chiller to make chilled

water for cooling. Another is the development for commercial product of small

capacity absorption chiller-heater for housekeeping. It is able to substitute

the electric packaged air-conditioner which is occupied most portion of electric

peak load.

1) Development of absorption chiller driven by low grade

hot water for district cooling and heating. In the present, The hot water

condition inlet 95℃

and outlet 80℃,

is supplied to drive an absorption chiller for district cooling. But if the

hot water is supplied at inlet 95 and outlet 55℃ in same pipe network, the

cooling capacity is increased to 2.4 times with same hot water flow rate.

For this purpose, The consortium comprised Century, Carrier, KDHC(Korea district

heating corp.). and POSCO(Phohang steel corp.) and developed the pilot unit,

40 usRT, from 1998 to 1999 which is installed in the office building of KDHC

and is operating for two years. The primary character of this system is that

the absorption chiller has auxiliary absorber and auxiliary generator to be

driven by low grade hot water to 50℃. And, the auxiliary solution heat exchanger and low

temperature solution heat exchanger is added to enhance COP. Even though the

achieved COP is 0.6 which is less than that of commercial product 95/80℃, 0.7 and

The size is 1.3 times and the cooling tower is needed large capacity, hot

water can be supplied to many unit and the cost of pipe network can be decreased.

The following figure 2 and 3 shows the cycle and duhring diagram.

|

|

|

|

Fig.

3. Cycle diagram of single effect-double lift absorption

2) Commercializing of household small absorbtion air-conditioner

To reduce the peak load of electricity, it is commercialized

by century that is household small absorbtion air-conditioner, in stead of

electrically driven package air conditioner.

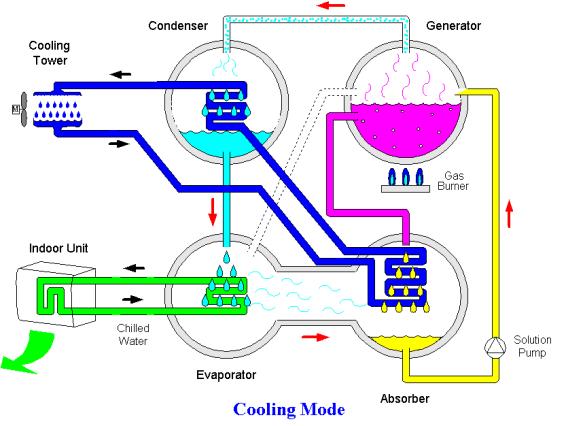

Which, applied double effect absorbtion cycle, is introduced

technological know-how from KO-GAS. The first commercialize product should

be produced in 2002 of which capacity is 3 usRT(The sort of capacity should

be extended to 1.5, 5, 7.5 usRT etc.).

This unit is adopted water cooled type for miniaturization

and effectiveness, of which C.O.P for cooling & heating is 0.8. And also

that is developed to multi type as three of indoor unit can be connected to

one outdoor unit. The cooling cycle of the unit and duhring diagram are shown

in Fig. 4 and 5.

|

|

Fig. 4. Cooling

cycle of small absorption air conditioner

|

|

Fig. 5. Duhring diagram of small absorption air conditioner.